Hospital

CANON AMERICAS HEADQUARTERS

Commercial

CARNEGIE 57

Residential

1 WORLD TRADE CENTER - STEAM UTILITY PROJECT

Office Building

WORLD TRADE CENTER FOUNTAINS

Fountain

NYU COGENERATION EXPANSION

CoGeneration

CREEDMOOR PSYCHIATRIC CENTER

Hospital

200 WEST STREET - GOLDMAN SACHS

Office Building

ONE BRYANT PARK COGENERATION PLANT

Power Generation

270 GREENWICH

Residential

Instrumentation & Control (I&C): FMMC and FMEC are proudly engaged in several instrumentation projects. The instrument technicians provide a unique skill set required to calibrate, install, and perform continuity and functional testing for a wide range of process instrumentation. Typically found on power generation projects and other Operations & Maintenance contracts on existing power plants, the I&C techs have also successfully diagnosed and corrected instrumentation and programming issues associated with multiple control systems and manufactures. Our I&C techs have installed instruments including flow elements, pressure indicators and transmitters, temperature indicators and transmitters, in-line specialties and thermowells, level and pressure transmitters, switches, controllers, control valves and multiple position actuators, and all air and water tubing and weather protective enclosures associated with a fully functional instrumentation system. Installation services also include emissions control and monitoring, or CEMS, sampling lines and systems. Most power generation projects have included the installation, programming, and start up support for DCS and PLC based control systems including HMI graphic displays and computerized systems.

Millwrights: FMMC is proud to employ millwrights. Millwrights install, repair, replace, modify and dismantle machinery and heavy equipment. Their responsibilities require a wide range of skills from understanding plans and specifications and pouring concrete to diagnosing and solving mechanical and electromechanical problems. Millwrights will handle all receiving, unloading, rigging, and assembly of rotating equipment and machinery such as turbines and pumps. To move light machinery, millwrights may use pulleys and cables. In other cases, they need hydraulics, lift trucks, cranes or other methods to position the machinery. Because they often decide what devices to use, millwrights must know the load-bearing properties of ropes, cables, hoists, cranes and other rigging apparatus and gantry systems. When assembling machinery, millwrights fit bearings, align gears, wheels, shafts and couplings, and attach motors and belts. Precision leveling and aligning may be critical in the assembly process. Consequently, millwrights must have strong mathematical skills so that they can measure angle heights, distances, and material dimensions and perform simple or complex layouts, often in three dimensions. Millwrights also use many hand and power tools, including but not limited to oxy-fuel torches, welders, machine tools, grinders, and pneumatic and electrical power tools. Increasing automation in most industries means millwrights install and maintain more sophisticated machines. The work often requires special care, calibrations, and knowledge. In addition to installing and dismantling machinery, many millwrights repair and maintain equipment. This includes preventive maintenance such as lubrication and fixing or replacing worn parts.

ASME Certified: FMMC currently holds the “S” and “U” authorization and stamps from the ASME for new construction work and an “R” authorization and stamp from National Board for repair work. These stamps allow FMMC to perform work on a variety of Boilers and Pressure vessels ranging from 3 pressure Heat Recovery Steam Generator (HRSG) assembly, repairs of existing utility boilers, repairs to chiller pressure vessels and alteration of any kind. In order to maintain these authorizations from the issuing jurisdictions, FMMC participates in a tri-annual review of our quality control procedures and practices and review of completed work with ASME and the National Board.

FMMC has utilized these authorizations on many projects including the Assembly of HRSGs at Caithness Long Island Power Station and the Empire Generating Station. We conduct repairs to existing boilers at power stations in the tri state area and have done modification work to York and Carrier chillers.

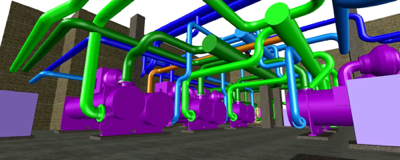

Engineering and Drafting: FMMC employees (9) draftsman and (5) NYS PE licensed engineers within our current staff. Engineering services range from hydronics and piping to structural and rigging plans. The drafting department is BIM/3D capable and very familiar with the advantages and troubleshooting associated with coordination with other trades. Our engineering and drafting department is one of the reasons that separate FMMC from other mechanical contractors. Our in-house engineering resource and experience allows for engineering and value engineering services that often benefit the overall project. Our draftspersons have the following skills:

•Proficiency in AutoCAD 2013 MEP & 2014 3D BDS, and Microsoft applications

•Multiple job trade coordination experience using BIM (Building Information Modeling)

•Knowledge of AutoDesk Revit and NavisWorks

•Familiarity with Architectural, Structural, and MEP drawings and current technology

•Knowledge of general drafting practices and procedures

•Develop and approve accurate layouts, assembly drawings, and details

•Prepare plans and layouts for equipment or system arrangements and space allocation.

•Specific knowledge of mechanical systems associated with commercial and industrial pipe, valves, and fittings.

•The ability to recognize cost effective routing of piping, pipe supports, and accessories is expected.

•Ability to coordinate between contract drawings and sub-vendor drawings for coordination of space and layout.

•Understanding of external ex-references, model/paper space

•PDF creation, plotting and preparation of drawing packages for submittal packages for engineer approval

•Processing of shop drawings and fabrication drawings and bills of materials.

•Develop and send RFI’s relating to piping and equipment coordination

•Knowledge of Imperial and Metric Units

•Ability to ensure accuracy of the designed product or concept for the specific project and the

organization

•Ability to field measure as required

•Ability to bring a projects’ drafting tasks to completion including management and completion of redline changes and submission of final as-built drawings for the client

Fabrication Shop: FMMC owns and operates a piping fabrication shop adjacent to the home office where a significant portion of our prefabrication and equipment pre-assembly takes place. The shop averages between 50,000 to 70,000 diameter inches of welded joints annually. An ASME code boundary area exists for performing boiler code joints.

Some of the equipment used in the shop includes a vertical band saw, pipe end prep tables, submerged arc welding system, MIG welding equipment, pulse spray arc welding equipment, and gantry crane with hoist. Utilized equipment in the shop for loading and handling fabrication includes 2.5T, 5T, and 6T forklifts, and hydraulic boom trucks. FMMC owned trailers utilized in transportation to the projects include hi flats, stretch trailers, and single & double drops.